We cannot solve our problems with the same thinking we used when we created them

— Albert Einstein

Greetings from Finland, where the future of agriculture reform lies in the remarkable potential of spirulina microalgae!

TL;DR:

Here are the key benefits of this agricultural reform:

- A substantial 90% decrease in ammonia emissions in Finland, with similar results expected in other countries.

- Significant reduction in CO2 emissions in the agriculture sector, amounting to approximately 10% of the total CO2 produced by the transportation sector.

- Decreased methane production from cows and minimized nutrient runoff from fertilizers.

- Introduction of decentralized electricity production through a new-generation wood gas generator that emits no carbon dioxide or particulate matter. Farmers can supply excess electricity to the national power grid and earn income from it.

These remarkable effects make it fitting to confidently label this initiative as an agricultural reform. The blog also highlights additional innovations in the field.

In the pursuit of climate-wise business practices, it is important to recognize that wealth does not inherently generate wealth. In reality, the ultimate source of prosperity lies in food production.

Today, we stand on the cusp of a breakthrough, finally harnessing the full potential of microalgae—a goal that has captivated scientists since the establishment of the first large-scale production facilities in the 1960s.

Spirulina demonstrates exceptional growth capabilities, with the ability to multiply its biomass up to fourfold in a single day. This rapid growth rate surpasses that of most plants, making Spirulina an efficient biomass producer. Its accelerated growth potential presents an opportunity for sustainable resource utilization and enhanced productivity in agricultural systems.

Spirulina boasts a distinctive nutritional profile, surpassing conventional plant-based sources such as soybeans. It contains approximately twice the protein content of soybeans and offers a broader spectrum of biocomponents, including phycocyanin, DHA (docosahexaenoic acid), EPA (eicosapentaenoic acid), and GLA (gamma-linolenic acid). These biocomponents contribute to Spirulina’s nutritional richness and provide additional health benefits.

Although Spirulina is considered a microorganism, its growth rate may not be as fast as certain bacterial species like Vibrio natriegens, which can double their population within approximately 10 minutes. However, Spirulina’s growth rate is still significantly faster than most plants, allowing for rapid biomass production and efficient resource utilization in agricultural systems.

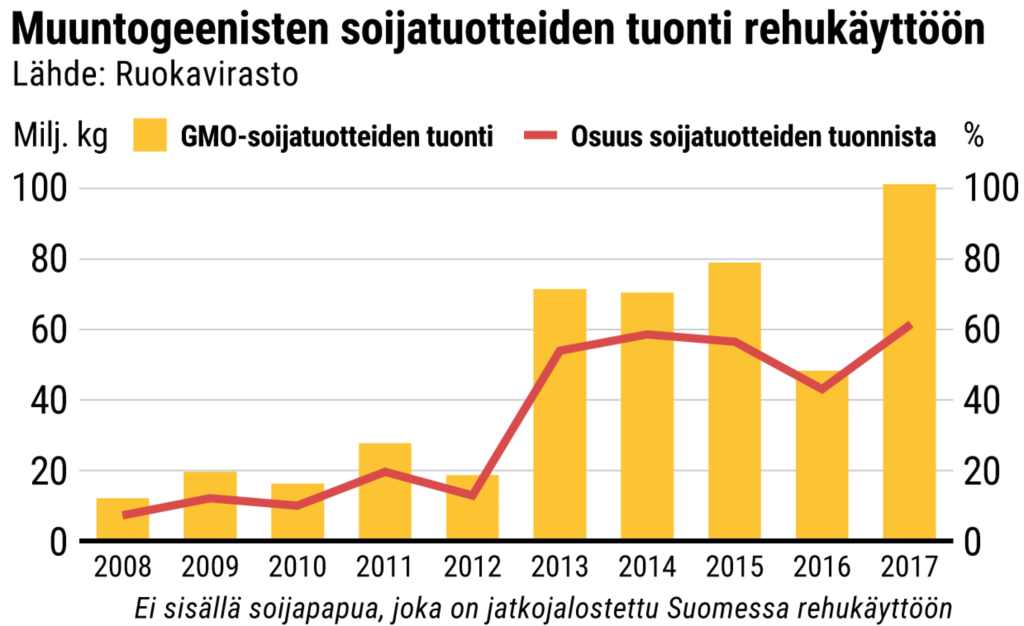

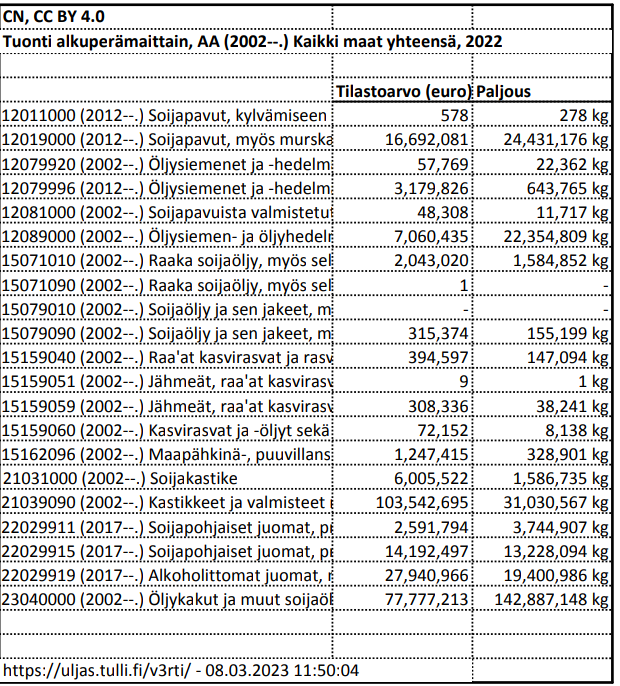

In Finland, we are embarking on an ecological revolution in agriculture by replacing genetically modified organism (GMO) soybean with sustainable Spirulina. Currently, the import of GMO soybean into Finland continues to rise steadily, with the import volume reaching over 260 million kilograms in 2022.

Allow me to summarize this intricate journey concisely, with the assistance of my loyal companion, Chat-GPT.

Fifteen years ago, I embarked on a journey as an inventor, focusing initially on prototypes involving magnetic bearings and LED technology. However, around a decade ago, my attention shifted towards the study of microalgae. After years of dedicated research, I reached a point where I felt confident in my understanding and promptly imported my first batch of microalgae from America, embarking on the cultivation and testing of these groundbreaking innovations. I gave this project a name: Bonsai Ecosystem (Boneco).

As an inventor, I consciously chose not to seek patents or protection for my discoveries. In our world on the brink of collapse, it is imperative that we transcend the pursuit of personal gain and financial success. Mainstream media predominantly fixates on the issues of methane and CO2 emissions, yet the problems we face are far more complex. It would be misguided to assume that the solution lies in completely abandoning traditional agriculture and adopting unconventional diets or solely relying on electric vehicles.

In Ireland, for instance, the government is contemplating legislation mandating the culling of 10% of the cow population as a climate-saving measure. This is merely the initial step on a path where beef prices will skyrocket, eventually surpassing the cost of rare and coveted wines.

While I remain hopeful for collaboration anywhere on this planet, I must express my disappointment with the current situation in Finland. Unfortunately, the circumstances here do not foster the development of green technologies like mine. Despite reaching out to numerous individuals in both the private and public sectors, I have encountered nothing but hollow words of encouragement and mere gestures of approval.

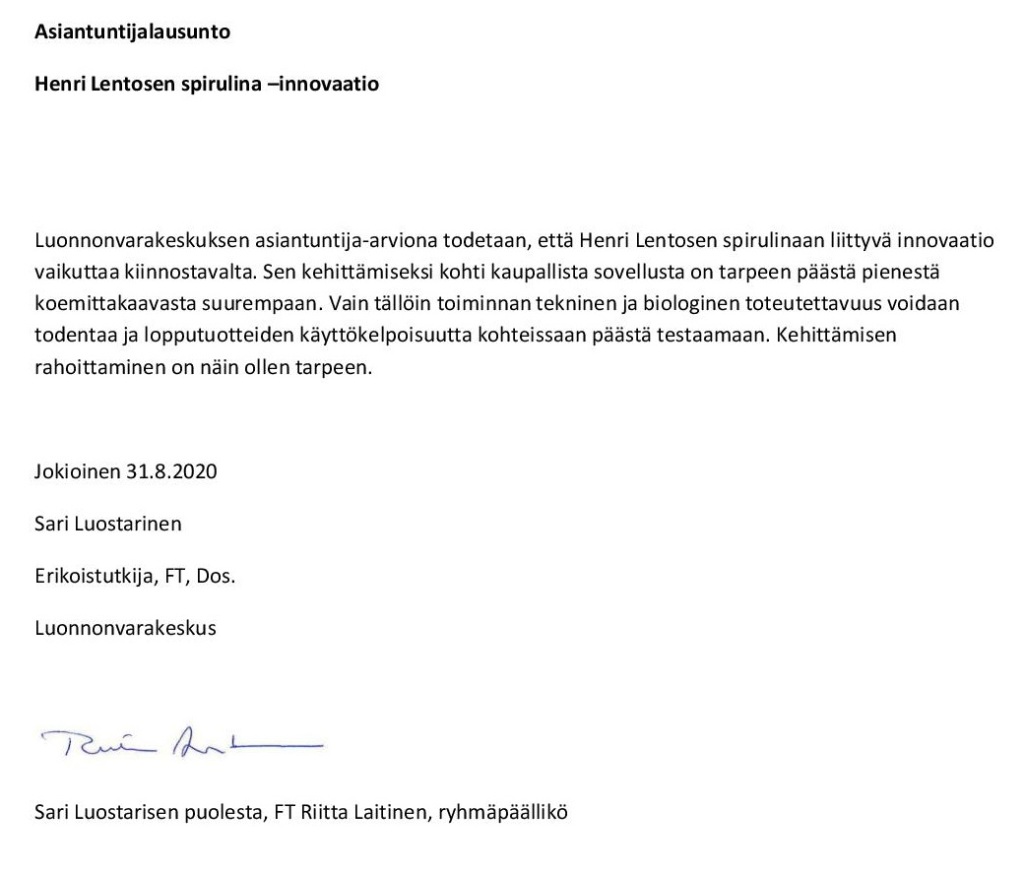

The government’s assistance, albeit limited, came in the form of a letter of recommendation from Luke (Natural Resources Institute Finland) experts. They suggested that funding should be provided to support the development of a pilot-scale system for my project.

On my project’s previous website, you will find an extensive list of sponsors, including prominent entities like the Finnish government’s Vapo (now renamed Neova). Regrettably, their support extended only as far as providing peat for the project. This disillusionment has cast a shadow over my perception of Finland, a country renowned for its achievements and standing in the world.

Only a few sponsors contributed a significant amount of funding, earning them the title of ‘honour sponsor.’ However, the combined contributions were still insufficient to finance the construction of a pilot scale facility.

It is disheartening to observe that both governments and major players such as Neste, with whom I had several Teams meetings in 2020, seem to prioritize greenwashing over actively addressing the urgent global issues related to ecosystems and climate. If these influential entities were to collaborate, we could currently be celebrating a significant step towards healing the planet. Unfortunately, it appears that the larger mission of finding sustainable solutions for these global problems is not a priority for them.

Believe me, over the past 8 years, I have made extensive efforts to reach out to various entities in Finland. I have sent thousands of emails and made countless phone calls. Even the leader of WWF in Finland personally informed me that this particular project does not align with their strategic focus. While it was a rare occasion to receive a direct response, most of the time, I have been ignored along with my project.

Last year, I established a non-profit organization called Tulevaisuusopisto ry (Academy of the Future). On our YouTube channel, you can witness the various stages of the project’s development.

https://m.youtube.com/@tulevaisuusopistory7505

Should you wish to contribute to this endeavor, I will create a sponsor list for the English version of the website. Please do not hesitate to contact me so that I may include your company’s name among our esteemed supporters.

Contact information:

Email: tulevaisuusopisto@gmail.com

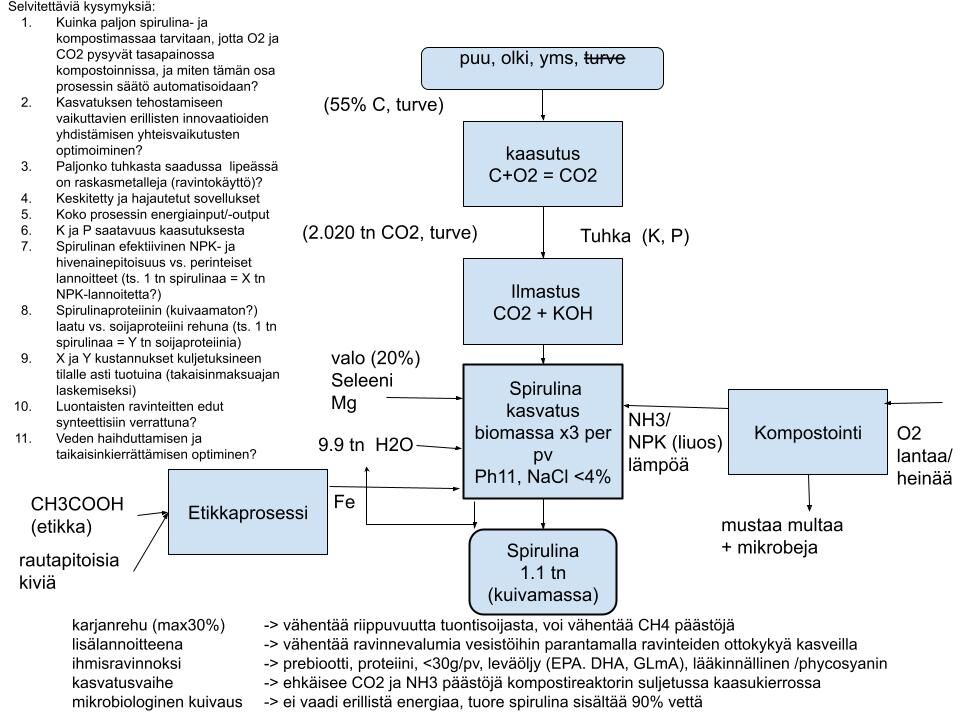

Now, let us delve into the summary extracted from Chat-GPT. Additionally, I will provide an image of the system’s process, which I intend to translate into English in due time, as it remains a work in progress even in its Finnish form.

Yours truly,

Henri Markku Mikael Lentonen, Futurist & Inventor

More detailed explanation can be found in these links:

- Woodgas generator

The implementation of wood, peat, or straw-based gas generation systems in farms for sustainable spirulina cultivation holds the potential for significant benefits. Besides enhancing energy efficiency, waste management, and carbon sequestration, it enables farms to supply excess electricity to the national grid. This integrated approach contributes to a sustainable future, where farms become power generators while actively reducing CO2 emissions.

2. New generation PBR combined with Aerobic Compost Reactor: The project integrates a new type of photobioreactor (PBR) technology with an aerobic compost reactor. This innovative combination enables efficient cultivation of microalgae while simultaneously converting organic waste into nutrient-rich compost. This synergy contributes to waste management, sustainable agriculture, and carbon sequestration.

3. Using Spirulina as Feed for Cows and in Farming Fields as Fertilizer:

Spirulina, a nutrient-rich microalgae, holds great potential as a feed source for cows and as a natural fertilizer for farming fields. This section explores the benefits and applications of utilizing spirulina in agriculture.

Agriculture reform plays a crucial role in addressing environmental challenges and promoting sustainable practices. One such innovation is the integration of spirulina and closed-loop compost systems, which offer multiple benefits for the environment, farmers, and the overall ecosystem.

The cultivation of prebiotic spirulina, a nutrient-rich microalgae, presents a unique opportunity to reduce methane emissions from cows. By incorporating spirulina into their diet, cows produce less methane, a potent greenhouse gas. This not only contributes to mitigating climate change but also helps in preserving air quality and reducing the ecological footprint of livestock farming.

Spirulina exhibits an optimal pH range of 9-10, while other microalgae tend to thrive at a neutral pH of 7. This unique characteristic of spirulina provides significant advantages in terms of microbiological safety due to the inhibitory effect of high pH on pathogen multiplication. As a result, spirulina, a type of blue-green algae, stands out as the most beneficial microalgae. Furthermore, spirulina contains essential fatty acids such as EPA (eicosapentaenoic acid) and DHA (docosahexaenoic acid), which are typically found in fish oil. Additionally, spirulina also contains GLA (gamma-linolenic acid), a component that is abundant in breast milk but absent in fish oil.

The implementation of closed-loop compost systems brings significant advantages. Traditionally, raw manure application to fields releases ammonia and CO2 into the atmosphere. However, with closed-loop composting, organic waste is converted into nutrient-rich compost, which can be used as a natural fertilizer. This eliminates the release of harmful gases, such as ammonia and CO2, resulting in improved air quality and reduced greenhouse gas emissions.

Furthermore, closed-loop composting helps prevent nutrient runoff into water bodies. Excessive use of chemical fertilizers often leads to nutrient leaching, causing water pollution and harmful algal blooms. By optimizing nutrient utilization through spirulina cultivation and efficient composting, plants can uptake nutrients more effectively, minimizing the need for excessive fertilizers. This not only safeguards water quality but also promotes cost savings for farmers.

The integration of spirulina and closed-loop compost systems in agriculture reform offers a holistic approach to address methane emissions, reduce greenhouse gas emissions, improve air and water quality, and enhance nutrient utilization efficiency. It is a multiple win-win solution that benefits the environment, farmers, and the overall sustainability of our agricultural practices.

When ammonia is released to the atmosphere, it can react with other compounds to form nitrous oxide, a potent greenhouse gas that contributes to climate change.

Note: nitrous dioxide has CO2 equivalent of about 300 and lifeage on atmosphere about 100 years, also it destroys ozone, so it is maybe the worst gas for the climate and planet, as for comparison the methane has only CO2 equivalent of 25 and lifeage on atmosphere only 12 years also methane is a part of forming new ozone.

By composting manure in a reactor and capturing the gases that are released, the closed loop system can significantly reduce the amount of ammonia that is released to the atmosphere. This reduction in atmospheric ammonia can help to improve air quality and reduce the formation of harmful particles.

Note: if every farmer on Finland would join the agriculture reform, we could cut off 90% of Finlands ammonia releases and 10% amount of CO2 compared to what all traffic produces on atmosphere every year. The numbers would be similar globally.

Using spirulina as a fertilizer will reduce the amount of synthetic fertilizer that is applied to the fields. This, in turn, will reduce the amount of nutrients that leach into nearby water bodies and contribute to eutrophication (excessive nutrient enrichment) of those waters. Furthermore, spirulina can absorb and remove nutrients from wastewater and agricultural runoff, which can help to improve water quality.

Note: adding apirulina on hydroponics will increase the yield as the plants can take more effectively the nutrients, the mechanisms based on the positive effect on the microbes that work symbiotic with plants roots. This is called “biostimulation” as spirulina isnt really a fertilizer in terms of NPK, yet it does offer some fertilizer value also and especially micronutrients.

https://www.sciencedirect.com/science/article/abs/pii/S0304423822001674

Here is a categorized list describing the key components of the agriculture reform:

- Microalgae Spirulina Reactor:

- Utilizes microalgae, specifically spirulina, to produce oxygen.

- Provides oxygen to support the aerobic compost reactor.

- Aerobic Compost Reactor:

- Facilitates composting process in an oxygen-rich environment.

- Generates CO2 as a byproduct.

- Supplies CO2 to the microalgae spirulina reactor.

- Woodgas Generator:

- Operates on peat or wood to produce electricity.

- Directs flue gas through lye solution for CO2 and particle capture.

- Reduces stress on the climate by minimizing CO2 emissions.

- Closed Loop Gas Exchange System:

- Ensures efficient gas exchange between the microalgae reactor and compost reactor.

- Air pumps deliver ammonia gas and CO2 from the aerobic compost reactor to the microalgae.

- Prevents spontaneous composting of raw manure in the field, reducing CO2 and ammonia emissions.

- Nutrient Recycling:

- Liquid compost produced in the aerobic compost reactor contains valuable nutrients.

- Nutrients from compost are utilized to support the growth of spirulina in the microalgae reactor.

- Spirulina as Cattle Feed:

- Spirulina, being prebiotic, is fed to cows.

- Expected to reduce methane production in cows, contributing to lower greenhouse gas emissions.

Climate:

- Carbon Reduction:

- The woodgas generator, operating on peat or wood, minimizes CO2 emissions during electricity generation.

- The closed-loop gas exchange system prevents spontaneous composting, reducing CO2 and ammonia emissions.

- The lye solution in the flue gas stream captures CO2, minimizing its release into the atmosphere.

- Methane Reduction:

- Feeding spirulina, a prebiotic, to cows aims to reduce methane production, a potent greenhouse gas.

Planet:

- Oxygen Generation:

- The microalgae spirulina reactor produces oxygen, contributing to increased oxygen levels in the environment.

- By utilizing oxygen from the microalgae reactor, the aerobic compost reactor supports efficient composting.

- Nutrient Recycling:

- The closed-loop system ensures the recycling of valuable nutrients from compost, reducing the need for synthetic fertilizers.

- The resulting liquid compost, rich in nutrients, supports the growth of spirulina and minimizes waste.

Humankind:

- Sustainable Resource Use:

- The agriculture reform promotes efficient resource utilization by recycling nutrients and minimizing waste.

- It reduces reliance on synthetic fertilizers and contributes to a more sustainable agricultural system.

- Health and Nutrition:

- Spirulina, provided as cattle feed, offers nutritional benefits to the animals.

- The prebiotic properties of spirulina may positively impact the digestive system of cows.

By implementing these measures, the agriculture reform not only addresses climate concerns by reducing emissions but also promotes sustainability, nutrient recycling, and potentially improved health outcomes for both animals and humans.

Climate:

- Water Conservation: Spirulina cultivation saves water up to 4 times compared to soybean cultivation.

- Carbon Sequestration: Spirulina absorbs approximately 2 kilograms of carbon dioxide for every kilogram produced.

Ecosystem:

- Reduced Land Use: Spirulina requires about 20 times less land area compared to soybeans.

- Nutrient Efficiency: Spirulina needs about 5 times fewer nutrients than plants, reducing nutrient runoff and waste.

Humankind:

- Protein-rich Food Source: Spirulina contains nearly twice the amount of protein compared to soybeans, providing a valuable food source.

- Iron Supplementation: Spirulina contains approximately 10 times more iron than beef, offering a natural iron supplement.

- Economic Opportunities: The facility’s production capacity can generate significant revenue, providing economic benefits to the community.

- Sustainable Farming: The facility utilizes automation and efficient resource management, demonstrating sustainable farming practices.

Improvements and Optimization in Agriculture Reform Facility:

- Enhanced Automation Systems:

- Integrate advanced automation technologies for precise control and monitoring of various parameters such as temperature, humidity, CO2 levels, and nutrient distribution.

- Implement smart sensors and actuators to optimize resource utilization and minimize wastage.

- Develop a user-friendly interface for efficient management and control of the facility.

- Integration of Microalgae Spirulina Reactor:

- Optimize the design and operation of the microalgae spirulina reactor to maximize oxygen production and nutrient absorption.

- Enhance the efficiency of carbon dioxide (CO2) capture and utilization by the microalgae to promote sustainable growth and reduce greenhouse gas emissions.

- Aerobic Compost Reactor:

- Improve the composting process in the aerobic reactor to accelerate decomposition and enhance nutrient conversion.

- Implement advanced aeration systems to facilitate microbial activity and optimize compost quality.

- Woodgas Generator with Flue Gas Treatment:

- Enhance the woodgas generator system to improve combustion efficiency and minimize emissions.

- Integrate effective flue gas treatment mechanisms to capture CO2 and remove particulate matter before releasing into the atmosphere.

- Closed Loop Gas Exchange System:

- Develop a comprehensive gas exchange system to capture and redirect gases such as ammonia and CO2 from composting to the microalgae reactor.

- Optimize the gas transfer efficiency to ensure effective nutrient recycling and minimize environmental impact.

- Nutrient Recycling and Circular Economy:

- Explore innovative methods to utilize the liquid compost derived from the facility as a nutrient source for spirulina cultivation.

- Implement closed-loop nutrient cycling strategies to minimize the reliance on external fertilizers and reduce waste generation.

- Prebiotic Spirulina Feed for Livestock:

- Research and develop strategies to incorporate spirulina as a prebiotic feed for livestock, aiming to reduce methane emissions and improve animal health.

- Continuous Research and Development:

- Foster ongoing research and collaboration to identify further improvements and optimize the overall performance of the agriculture reform facility.

- Stay updated with emerging technologies and scientific advancements to drive continuous innovation in sustainable agriculture practices.

By implementing these improvements and optimizations, we aim to create a more efficient, sustainable, and environmentally friendly agriculture reform facility that can contribute to healing the planet, supporting climate resilience, and ensuring the well-being of humankind.

There are several ways to maximize the efficiency of a reactor model that utilizes microalgae and aerobic compost in a closed loop system. Here are some suggestions:

- Optimize the growth conditions for microalgae: The efficiency of the system can be improved by maximizing the growth rate and productivity of the microalgae. This can be achieved by optimizing factors such as light intensity, temperature, pH, nutrient levels, and gas exchange rates.

- Optimize the composting process: The composting process can be optimized to ensure that it is efficient and produces minimal emissions. This can be achieved by controlling factors such as temperature, moisture, and aeration levels.

- Use high-quality inputs: The inputs used in the system, such as manure, should be of high quality to ensure that they are rich in nutrients and do not contain harmful contaminants. This can improve the efficiency of the system and reduce the risk of negative impacts on the environment.

- Monitor and control the system: Regular monitoring and control of the system can help to identify any issues or inefficiencies and allow for adjustments to be made. This can involve measuring factors such as nutrient levels, pH, temperature, and gas exchange rates.

- Optimize the harvesting process: The harvesting process can be optimized to ensure that the maximum amount of biomass is collected with minimal waste. This can involve optimizing factors such as harvesting frequency, biomass concentration, and harvesting methods.

- Optimize the growth conditions for microalgae:

- Light intensity: The system should be designed to maximize the amount of light that reaches the microalgae. This can be achieved by using transparent materials for the reactor walls and optimizing the positioning of the reactor to maximize exposure to sunlight.

- Temperature: The optimal temperature for microalgae growth depends on the species, but is generally between 20-30°C. The temperature should be maintained within this range to maximize growth.

- pH: The optimal pH for microalgae growth is generally between 7.0-9.0. The pH should be monitored regularly and adjusted as necessary to maintain optimal conditions for growth.

- Nutrient levels: Microalgae require nutrients such as nitrogen, phosphorus, and potassium for growth. The nutrient levels should be optimized to maximize growth while minimizing waste and runoff.

- Gas exchange rates: The reactor should be designed to allow for efficient gas exchange, which is necessary for microalgae growth. This can be achieved by using aeration stones and air pumps to circulate air and allow for gas exchange.

- Optimize the composting process:

- Temperature: The composting process should be maintained at a temperature of 50-60°C to ensure efficient breakdown of organic matter and production of compost.

- Moisture: The moisture level should be maintained at around 60% to ensure efficient composting.

- Aeration levels: The composting process requires oxygen to support aerobic decomposition. The system should be designed to allow for efficient aeration, which can be achieved by using aeration stones and air pumps.

- Use high-quality inputs:

- Manure: The manure used in the system should be of high quality to ensure that it is rich in nutrients and free of harmful contaminants such as antibiotics and heavy metals.

- Other inputs: Other inputs, such as food waste or other organic matter, should also be of high quality to ensure efficient composting and optimal growth of microalgae.

- Monitor and control the system:

- Nutrient levels: The nutrient levels in the system should be monitored regularly to ensure that they are optimal for growth.

- pH: The pH should be monitored regularly and adjusted as necessary to maintain optimal conditions for growth.

- Temperature: The temperature should be monitored regularly to ensure that it is within the optimal range for both microalgae growth and composting.

- Gas exchange rates: The gas exchange rates should be monitored regularly to ensure that they are efficient and supporting optimal growth and composting.

- Harvesting: The harvesting process should be optimized to ensure that it is efficient and minimizes waste.

- Optimize the harvesting process:

- Harvesting frequency: The frequency of harvesting should be optimized to ensure that the maximum amount of biomass is collected with minimal waste.

- Biomass concentration: The system should be designed to allow for efficient separation of biomass from the liquid, which can be achieved through processes such as centrifugation or filtration.

- Harvesting methods: The harvesting methods should be optimized to ensure that they are efficient and minimize damage to the microalgae.

By optimizing these factors, the efficiency of a reactor model that utilizes microalgae and aerobic compost in a closed loop system can be maximized, reducing greenhouse gas emissions and improving sustainability.

The effect of flashing LED lights on the growth of microalgae is based on the phenomenon called “light-dark cycles” or “light-dark regime”. Microalgae require light for photosynthesis, which is the process through which they produce organic compounds and oxygen from carbon dioxide and water. However, if the light intensity is too high or constant, it can lead to photoinhibition, a condition in which the photosynthetic machinery is damaged, and the microalgae growth is reduced.

By using flashing LED lights with a duty cycle of 10%, the microalgae are exposed to short pulses of light, followed by periods of darkness. This type of light-dark regime can help to avoid photoinhibition and increase microalgae growth. Additionally, the flashing light creates a turbulent flow within the photobioreactor, which enhances the mass transfer of nutrients and gases to the microalgae cells, further improving their growth.

Overall, using flashing LED lights with a duty cycle of 10% can increase the efficiency and productivity of the photobioreactor, as well as optimize the growth conditions for the microalgae.

Note: also, as we flash the LEDs, they act on certain low voltage area as peltiers, cooling themself down. Without any heat we don’t need even a passive cooling system for LEDs which will save money and resources but also, their lifeage will increase exponentially since heat is the primary mechanism LEDs degrade in time, here is a study about the peltier phenomenon on LEDs:

https://phys.org/news/2012-03-efficiency.amp

With 10 kHz and 10% dutycycle, we can save in theory 90% of electricity and produce almost 3x more biomass, since we can decrease the photoinhibition into almost zero so this is a major thing to apply in the new generation microalgae culture system:

Also, we can increase biomass by 1.5x with very weak magnets, too strong magnets decrease the biomass:

https://www.sciencedirect.com/science/article/abs/pii/S0922338X98801360

The term “FLE” stands for Flashing Light Effect. It refers to a phenomenon where flashing or intermittent illumination of light can have certain effects or benefits in specific applications. The FLE is particularly relevant in the context of LEDs (Light-Emitting Diodes) and their operation.

Flashing LEDs provide several benefits in microalgae cultivation, including enhanced photosynthetic efficiency, mitigation of photoinhibition, optimal light distribution, reduction of photobleaching, and energy efficiency. By modulating the light exposure through intermittent pulses, flashing LEDs optimize microalgae growth, improve biomass production, and contribute to the overall sustainability of the cultivation process.

- Enhanced Photosynthetic Efficiency:

- Flashing LEDs, which involve intermittent light pulses, can improve the photosynthetic efficiency of microalgae, including Spirulina.

- Microalgae have specific light absorption and utilization patterns, and by modulating the light exposure through flashing LEDs, it is possible to optimize their photosynthetic activity.

- The intermittent light pulses allow microalgae to efficiently utilize the light energy during the on periods while minimizing energy dissipation during the off periods.

- This improved utilization of light energy leads to enhanced photosynthetic efficiency and higher biomass production.

- Mitigation of Photoinhibition:

- Photoinhibition refers to the process where excessive light exposure can damage the photosynthetic apparatus of microalgae, negatively impacting their growth and productivity.

- Flashing LEDs can help mitigate photoinhibition by providing periods of darkness or low light intensity between the light pulses.

- During the off periods of flashing LEDs, microalgae can recover from potential photodamage and prevent the accumulation of reactive oxygen species (ROS), which are harmful byproducts of excessive light exposure.

- By reducing photoinhibition, flashing LEDs contribute to the overall health and productivity of microalgae cultures.

- Optimal Light Distribution:

- Flashing LEDs enable better light distribution within the cultivation system, ensuring uniform illumination across the microalgae population.

- Traditional continuous lighting sources can lead to uneven light distribution due to shading effects caused by the self-shadowing of microalgae cells.

- By flashing LEDs, the light pulses can penetrate through the cell layers, reducing the shading effect and providing more uniform light exposure.

- This uniform light distribution promotes equal growth and biomass accumulation throughout the microalgae culture, resulting in improved overall productivity.

- Reduction of Photobleaching:

- Photobleaching refers to the degradation and loss of pigments, such as chlorophyll, in microalgae due to prolonged exposure to high-intensity light.

- Flashing LEDs with controlled light intensities and intermittent exposure can minimize photobleaching by allowing microalgae to recover during the off periods.

- The reduced light exposure during off periods helps maintain the stability and integrity of pigments, ensuring their optimal functionality in light absorption and photosynthesis.

- By minimizing photobleaching, flashing LEDs contribute to the preservation of photosynthetic pigments, leading to sustained growth and productivity of microalgae.

- Energy Efficiency:

- Flashing LEDs offer energy-efficient lighting options for microalgae cultivation systems.

- Compared to continuous lighting sources, flashing LEDs consume less energy since they are operated intermittently.

- This energy efficiency translates to cost savings and reduced environmental impact associated with energy consumption.

- By utilizing flashing LEDs, microalgae cultivation systems can achieve sustainable and economically viable production processes.

Extended LED Lifespan:

Excessive heat can degrade the performance and lifespan of LEDs.

The cooling effect during flashing reduces the thermal stress on the LEDs, extending their lifespan.

By maintaining optimal operating temperatures, the need for frequent LED replacements is minimized, resulting in cost savings.

Flashing LEDs will lead to increased efficiency and the occurrence of a cooling effect, similar to the Peltier element. This enhances LED performance, improves energy efficiency, extends LED lifespan, and opens up new potential applications in various fields.

By combining the benefits of weak magnetic fields, the utilization of discarded magnets it is possible to create an innovative microalgae cultivation system that enhances biomass production, optimizes biomass composition, and promotes energy efficiency.

- Influence of Weak Magnetic Fields on Biomass Increase:

- Magnetic fields with low intensity, such as those generated by weak magnets, have been found to increase the biomass of microalgae, including Spirulina.

- Studies have shown that exposure to weak magnetic fields stimulates the growth and enhances the biomass concentration of Spirulina cultures.

- The magnetic field triggers a stimulating effect on Spirulina, resulting in higher biomass production within the same cultivation time period.

- Utilization of Magnets from Broken Speakers:

- Discarded magnets, such as those found in broken speakers, can be repurposed for use in microalgae cultivation systems.

- These magnets can be strategically positioned within the cultivation environment to create a desired magnetic field strength.

- By repurposing magnets from trashed speakers, it is possible to harness their magnetic properties and apply them to enhance the growth and productivity of Spirulina.

- Improved Biomass Composition with Magnetic Field Application:

- Magnetic field treatment influences the composition of Spirulina biomass, resulting in higher protein and carbohydrate contents.

- Research has shown that magnetic field exposure can increase protein content by 105.1% and carbohydrate content by 133.2% compared to control cultures.

- The enhanced biomass composition offers potential benefits for the use of Spirulina as a food supplement or in various applications.

Note: I worked couple hours with the automation c++ code, and Chat-GPT provided 20 pages of the basic code, next I will chop these into more smaller and we build the whole code:

https://drive.google.com/file/d/1LadQrda4_0oWPn6iUyswDKRxiKF928tK/view?usp=drivesdk

I am excited to present to you an innovative opportunity for collaboration in revolutionizing greenhouse systems and contributing to the well-being of our planet. By embracing cutting-edge technologies and advancements, we can create a new generation of automated greenhouses that address the challenges of climate change and promote sustainable agriculture.

- Transformation of Automation Control:

- Advise against investing in outdated automation control systems due to high transformation costs.

- Recommend waiting for the development of new generation greenhouses that integrate advanced automation solutions.

- New Generation Greenhouses:

- Incorporate both green microalgae and plant cultivation for enhanced ecological benefits.

- Implement complex automation systems that regulate heat, CO2, O2, moisture, and ventilation.

- Collaborative Development:

- Join forces to develop next-generation automation systems tailored for the greenhouse environment.

- Explore the integration of multiple devices, including LEDs operating at 10 kHz, as well as advanced heat and aeration sensors.

- Leverage the capabilities of Chat-GPT to handle the intricacies of the automation system.

By embracing this collaborative effort, Chat-GPT and OpenAI can make a significant impact in mitigating climate change, benefiting humankind, and preserving our precious ecosystems.

Let’s embark on this journey together and shape the future of sustainable agriculture.

Automation Plan for Gas Adjustment in Spirulina and Compost Reactor:

- Components:

- Oxygen and carbon dioxide sensors: These sensors will measure the oxygen and carbon dioxide levels in the system.

- Arduino or similar microcontroller: It will receive data from the sensors and control the gas adjustment mechanisms.

- Gas flow control valves: These valves will regulate the flow of gases in the system.

- Lye injection system: This system will introduce lye into the gas loop to decrease CO2 levels if required.

- Gas exchange loop: The primary loop where gases are exchanged between the photobioreactor and the compost reactor.

- Sensor Integration:

- Connect the oxygen and carbon dioxide sensors to the Arduino.

- Program the Arduino to read the sensor data and process it for control actions.

- Gas Adjustment Control:

- Establish target oxygen and carbon dioxide levels for the compost reactor and Spirulina growth.

- Set up control algorithms on the Arduino to compare the measured gas levels with the target levels.

- Based on the comparison, determine the necessary adjustments to the gas composition.

- Primary Gas Loop Adjustment:

- Use the Arduino to control the gas flow control valves in the primary gas exchange loop.

- If the oxygen levels are low in the compost reactor, increase the gas flow from the photobioreactor (containing spirulina) to supply more oxygen.

- If the carbon dioxide levels are low in the photobioreactor, increase the gas flow from the compost reactor to supply more carbon dioxide for spirulina growth.

- Secondary Aeration Loop with Lye:

- Since the compost reactor requires oxygen, avoid diverting gas from the compost reactor for CO2 adjustment.

- Instead, focus on maintaining the oxygen levels in the compost reactor by adjusting the gas flow from the photobioreactor.

- If the carbon dioxide levels in the primary loop are excessively high, activate the lye injection system to decrease CO2 concentration in the photobioreactor without compromising the compost reactor’s oxygen supply.

- Monitoring and Feedback:

- Continuously monitor the gas levels and system performance through the sensors and Arduino.

- Implement feedback control to make real-time adjustments based on the measured data.

- Fine-tune the control algorithms to optimize gas adjustments and maintain the desired gas concentrations.

- Safety Measures:

- Incorporate safety features and alarm systems to ensure proper functioning of the gas adjustment mechanisms.

- Implement fail-safe measures to handle any unexpected scenarios, such as system malfunctions or abnormal gas levels.

Improvements and Optimization in Agriculture Reform Facility with AI Integration:

- AI-Driven Automation Systems:

- Integrate advanced AI algorithms and machine learning models to optimize and automate various processes within the facility.

- Utilize AI-powered sensors and actuators to monitor and control parameters such as temperature, humidity, nutrient levels, and gas concentrations in real-time.

- Develop AI-based decision support systems to assist in resource allocation, predictive maintenance, and adaptive control.

- AI-Assisted Microalgae Spirulina Reactor:

- Implement AI algorithms to analyze and optimize the operation of the microalgae spirulina reactor, improving oxygen production and nutrient absorption.

- Use AI-driven predictive models to optimize the carbon dioxide (CO2) utilization by the microalgae, enhancing efficiency and reducing emissions.

- AI-Enabled Aerobic Compost Reactor:

- Deploy AI-based algorithms to optimize the composting process in the aerobic reactor, ensuring efficient decomposition and nutrient conversion.

- Utilize AI-driven monitoring systems to maintain optimal conditions for microbial activity and compost quality.

- AI-Controlled Woodgas Generator with Flue Gas Treatment:

- Integrate AI systems to optimize the combustion process in the woodgas generator, improving efficiency and reducing emissions.

- Employ AI algorithms for real-time monitoring and control of flue gas treatment mechanisms, ensuring effective CO2 capture and particulate removal.

- Intelligent Closed Loop Gas Exchange System:

- Develop AI-powered control systems to optimize the gas exchange process, capturing and redirecting gases like ammonia and CO2 from composting to the microalgae reactor.

- Utilize AI algorithms to fine-tune gas transfer efficiency and nutrient recycling, maximizing resource utilization and minimizing environmental impact.

- AI-Based Nutrient Management and Circular Economy:

- Implement AI-driven analytics and optimization algorithms to manage nutrient recycling and maximize the utilization of liquid compost as a nutrient source for spirulina cultivation.

- Utilize AI systems to analyze nutrient requirements, monitor nutrient levels, and provide precise recommendations for sustainable nutrient management.

- AI-Powered Livestock Feed Optimization:

- Utilize AI algorithms to analyze nutritional requirements and develop optimized spirulina-based prebiotic feed formulas for livestock, reducing methane emissions and enhancing animal health.

- Continuous AI Research and Development:

- Invest in ongoing AI research and development to stay at the forefront of emerging technologies and advancements in automation, machine learning, and data analytics.

- Collaborate with AI experts, researchers, and industry professionals to drive innovation and develop cutting-edge AI solutions for sustainable agriculture.

By integrating AI technologies into the agriculture reform facility, we aim to harness the power of artificial intelligence for efficient automation, data-driven decision-making, and optimization of resource utilization. This AI-driven approach will contribute to creating a sustainable and technologically advanced agriculture system that benefits the planet, supports climate resilience, and ensures the well-being of humankind.

If you made it all the way through here, finish your training by reading this book about spirulina industrial scale cultivation: after that you are a microalgae engineer:

https://drive.google.com/file/d/1XG_9SDADDWmx_BGheUjD8naGznMCS6Dr/view?usp=drivesdk